Pull dents quickly with the new Weld & Slide

Wednesday 29 October 2014

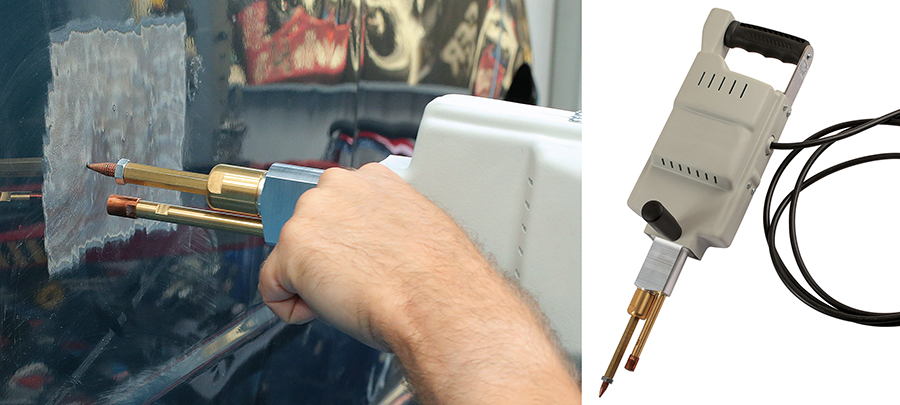

Traditionally dent pullers meant that a series of holes was drilled in the sheet metal to make the repair but that weakened the panel and the holes had to be filled. Then stud welding became popular but was time consuming and meant grinding off any remaining stud material after the pulling was completed. Now Power-TEC takes dent pulling to the next stage with its new Weld & Slide dent puller (part no 92436).

This is a slide hammer and resistance welder in one instrument; it is simply pressed onto the area to be repaired — the earthing rod and welding shaft are spring loaded — a button is pressed which welds the tip to the metal, and the instrument is pulled back along the shaft to complete the slide hammer action. Turn ninety degrees to break the weld, move along the dent and weld again. Each welding action tightens and shrinks the sheet metal before it is pulled back.

As the instrument provides the earth and welding tip circuit in a small, very focused area, it is ideal for the repair of electric and hybrid vehicles.